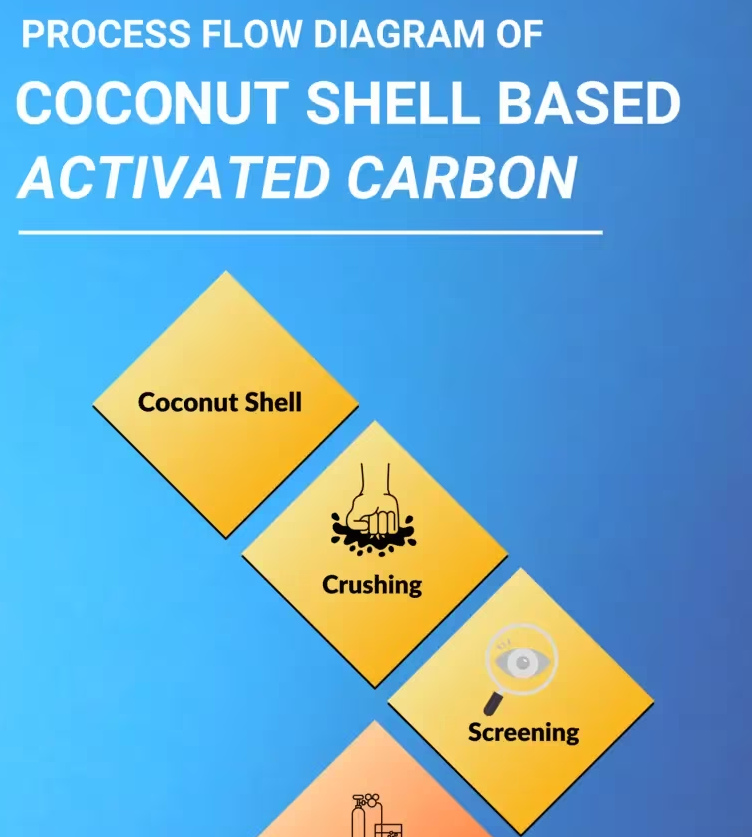

Process Flow Diagram of Coconut Shell Based Activated Carbon

Process Flow Diagram of Coconut Shell Based Activated Carbon

Our coconut shell based activated carbon is created at a high purity for excellent adsorption, and it’s also the most eco-friendly way to produce activated carbon. It has a wide range of uses, including the purification of liquids and gases, as well as food and drink processing.

In this article, we’ll describe the full process of how we make our high-quality coconut shell activated carbon.

Step 1: Cleaning & Drying

The first step in the process is selecting the best quality coconut shells, an eco-friendly choice as they are the byproduct of coconut processing and would otherwise be discarded. As a quality activated carbon supplier, we understand coconuts are an excellent choice for activated carbon because they boast a low ash content but at the same time they’re very hard and high in lignin. We clean and dry the shells thoroughly so they’re ready for the crushing

Step 2: Crushing

Once they’ve been cleaned, we add the coconut shells to a crusher so that the carbonization at later stages can happen more easily on a larger surface area. We don’t crush them down to dust, but instead leave enough of a surface area on each part of crushed coconut that can actively filter liquids and gases while remaining rigid. It’s at this stage we can select the particle size for our customers: small 200 mesh for gas adsorption and larger 20×40 granules.

Step 3: Screening

We monitor every stage of our process, and it’s at this point that particles are checked and separated according to the sizes required by customers. The particles need to be even for proper carbonization and activation, so here we remove any dust that is too small. This step is crucial in determining the final pore size of the activated carbon.

Step 4: Carbonization

In this stage, the main carbonization takes place in a low-oxygen environment with temperatures as high as 300-400°C. This step rids the new product of VOCs, so we are left with a high carbon product where we begin to create the pores it needs to filter effectively. As we heat the carbon slowly, it makes it super hard and stops it from being brittle and breaking. We always aim for a low ash content, and this process ensures Asiacarb offers our coconut based activated carbon at just 3%.

Step 5: Stock Chest

After heating the carbon to a very high temperature, it then needs to be cooled and stabilized so we let it settle to develop the hardness slowly. VOCs continue to dissipate from the carbon in this stabilization phase, making it even purer and giving it a much higher durability, delivering the highest quality product for our customers.

Step 6: Activation

This is where we turn regular carbon into activated carbon, and it’s the most important stage. We use either steam or CO2 to boost the temperature to a massive 900-1000°C. It’s at this stage where micropores are formed in each tiny piece of carbon, activating it and increasing the surface area exponentially. It’s here where we create the final moisture content of the carbon which we aim to keep at 10% or below, and also the CTC which we can create anywhere between 40-70% depending on customer requirements.

Step 7: Crushing

This is the second time the activated carbon is crushed and we tailor it to the sizes we offer. Some customers will need a very fine mesh such as 325 which is in activated carbon powder form, but others will require a granule size, and we offer a huge range of sizes so it’s specific for the application you need it for. Not only does this step keep the particle amounts uniform, but it also allows for the structural hardness to remain about 95%.

Step 8: Screening

A final stage of screening is needed to make sure that the particle sizes are correct for the specific order. It’s here that we remove any large chunks or fine dust from the activated carbon, so we can deliver the very best quality coconut shell activated carbon at the exact right sizes. This uniformity means that whether you need it for an activated carbon air purifier or an activated carbon water filter, it will work perfectly for the task at hand.

Step 9: Packaging

We package our activated carbon in 25kg plastic woven bags, or you can select a huge 500kg bags which are 500kg each. The way we package our activated carbon maintains all of the metrics it has been created with, such as pH stability and moisture content. We label each product with the specific parameter values for each customer, then ship it directly to its destination.

If you’d like to Learn more about sourcing activated carbon about our coconut shell activated carbon, or find out about our activated carbon prices, get in touch today to discuss your order.