Whether you need activated carbon powder for air and gas purification, or a pelletized product for an activated carbon filter, we are an activated carbon supplier in the heart of Jiangsu.

In this article, we’ll show you how we make one of our most in-demand products, wood based activated carbon, which is useful for chemical purification and water treatment as well as in the food industry for decolorization.

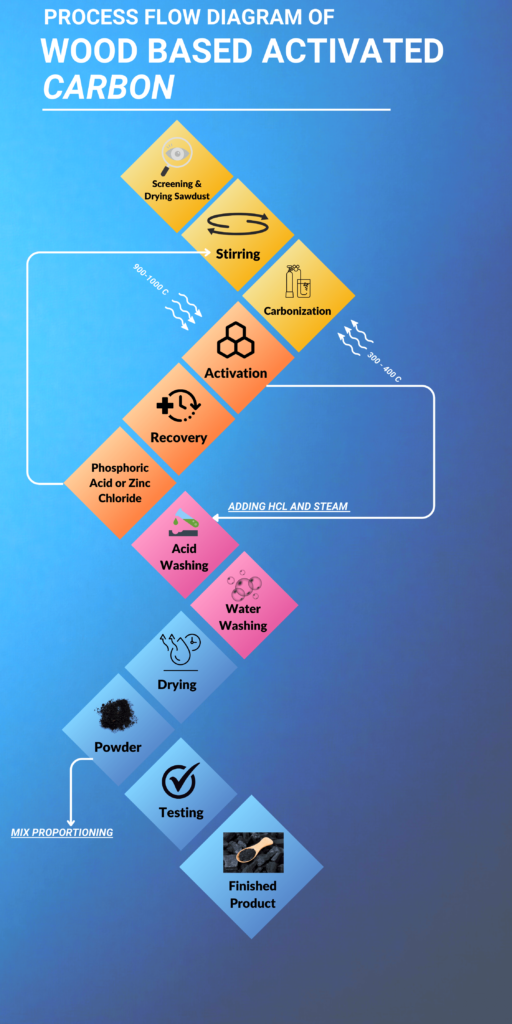

The quality of the material for activated carbon made with wood is essential, so here at Asiacarb we choose the best quality hardwood and softwood. We clean and treat the wood, removing any dirt and bark to give a low ash content but high carbon content. Once it’s been cleaned and processed, we dry it out thoroughly to remove the moisture which can affect the carbonization and activation processes.

The sawdust is now added to a stirring machine which ensures that any chemical treatments we add to the wood like phosphoric acid and zinc chloride are properly mixed through and distributed evenly. This is key for creating a high quality activated carbon product, and the activating agents are always added in the correct measures for the best quality results.

Once prepared, the wood is heated in a low oxygen environment to around 300-400°C which helps the creation of a high carbon product. The pores are beginning to form at this stage and the carbon content increases greatly as organic impurities are removed.

Now that the product has been carbonized, it can be activated at very hot temperatures of between 900-1000°C in our activated carbon factory. During this process, the surface area of the carbon particles are expanded and created using either steam activation which uses water vapor to help pores develop, or in some cases we use chemical activation to increase porosity and boost activated carbon adsorption capabilities. At times, it’s necessary to put this new product through acid washing which involves steam and hydrochloric acid to remove further inorganic compounds.

During the recovery phase, we recover any of the phosphoric acid and zinc chloride which has not reacted with the carbon and reuse it in the stirring step. This makes our operations more environmentally friendly and saves costs for both us and the customer, as we are not wasting valuable products.

Even though the wood based product has now been carbonized and activated, it can still contain impurities that we need to remove to give our customers the very best quality. An acid wash removes any ash and inorganic compounds so the adsorption efficiency is greatly increased, and unwanted materials are neutralized. This step ensures the highest quality of purity that can be used in pharmaceutical o food production, as well as water treatment.

We now need to remove the acids and impurities from the wood based activated carbon, and this is done with a water wash. We aim for all of our activated carbon products to have a neutral pH so it complies with the high industry standards, allowing it to be used in various filtration applications.

This is an important step in the process and must be done correctly to ensure the best results. The drying process will remove any extra moisture left over from the water washing to make sure all of our products have a moisture content of less than 10%. Not only does it make it easier to pack, but it also enhances the shelf life and overall stability of the product during transportation.

Now that we have the product almost finished, it’s time to turn it into a product of our customer’s exact requirements. We can powder it, make it granular, or pelletize it. If you want powdered activated carbon for adsorption, then we crush it to a powder of 325 mesh or below. For those looking for granular activated carbon for industrial activated carbon filters, you can choose a 4 x 8 mesh or a larger 8 x 30 mesh. When it’s pelletized activated carbon you need, opt for a small 1.5mm size or a large pellet of 7mm. If you need mix proportioning, we can blend a range of carbon grades together to create a product unique for your application.

We take extra care to ensure our products meet the recommended industry standards, so we test the adsorption capacity of the activated carbon by determining its iodine number, how durable it is with its hardness value which we aim to be 95% or above, a low ash content or below 3%, and a moisture content which is always less than 10% for a stable shelf life.

All that’s left to do is package the product and ship to our valued customers around the world. For smaller orders, you can choose it to be delivered in 25kg bags, or much larger 500kg sacks for applications that require a lot of activated carbon. Get in touch with us via phone or email to discuss your order.